Text By: Elton Pila (in Manica and Sofala); Hermenegildo Langa

Photos by: Jay Garrido & Cristiana Pereira

Industry Especial | Download

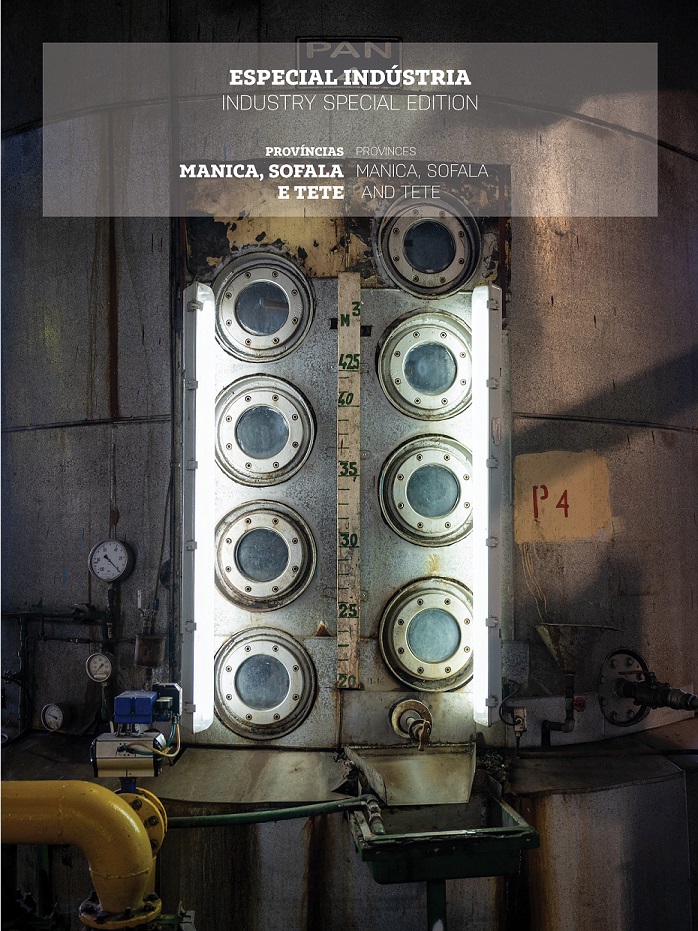

INDUSTRY SPECIAL EDITION

EDITORIAL

IN THE INDUSTRY’S CENTRE

The 3rd edition of the Industry Special has as its main focus the central region of the country, namely the provinces of Manica, Sofala and Tete, aiming to show the potential of the industrial sector in this region as well as its contribution to the national economy. In this edition, the potential of these provinces is addressed, especially in the area of agribusiness in Manica and Sofala, which has been developing significantly. This edition also highlights DECA (Desenvolvimento e Comercialização Agrícola, Limitada), which operates in the corn purchase and processing businesses. The company has built strong brands in Mozambique and intends to use these foundations to further grow and diversify its product range. Also in Sofala province, the Mafambisse Sugar Refinery stands out, one of the oldest sugar factories in Mozambique, which has made its contribution to the development of local communities. In the province of Tete, the focus is on the extractive sector, which is considered the epicenter of the province’s economy and promotes numerous SMEs, mainly providing services and goods.

Finally, it should be noted that the “Industry Special” editions have been positioning themselves as a platform for expanding the business and partnership network, at local and national level. For this reason, AIMO and Executive Moçambique reiterate their commitment to bring the Industry Special supplement to the general public throughout the six editions already announced in previous editions. At the end, a publication will be released condensing all the material collected, in an event in the format of an economic and industrial conference. For a dynamic, modern and competitive industry.

Osvaldo Faquir

Executive Director of AIMO (Associação Industrial de Moçambique)

FLASH NEWS

▶ IFPELAC and CETA join the training of industrial technicians

Establishing a partnership to share good practices in technical training was the objective of launching the training program for Mozambican industrial technicians, entitled “Train the Trainer”. The recently launched program aims to enable industrial technicians to perform better in the industrial sector, and has the support of the Alberto Cassimo Mozambican Institute for Vocational Training and Labor Studies (IFPELAC) and the South African company CETA.

▶ Government wants to improve fiscal policies for industry

The Government reaffirms its commitment to continue to improve fiscal, monetary and sectoral policies to facilitate the implementation of national and foreign investments in the Mozambican industrial sector. According to statements by the Prime Minister Carlos Agostinho do Rosário at the opening of the Economic Seminar on integrated industrialization, the government will do everything to promote the development of industry in the country.

▶ III Agricultural Marketing Forum launched

Urging producers and stakeholders to market the start of the 2021 agricultural campaign was the objective of the Launch of the III National Agricultural Marketing Forum. Held by the Ministry of Industry and Commerce, under the motto “Agricultural Marketing, Promoting Agribusiness and Industrialisation,” the event also served to publicise the interventions of economic agents in the agricultural marketing value chain, and to improve coordination between producers and actors in the productive and commercial value chain.

▶ Government launches “Promote Commerce” Project

The “Promote Commerce” project is an initiative recently launched by the Ministry of Industry and Commerce (MIC) and the European Union which aims to improve the business, trade environment and create competitiveness for exports in Mozambique.

From the set of objectives to be achieved with the project, it is also possible to model, contextually and structurally, the Made in Mozambique seal, to enhance the quality, certification and image of national production, as well as to consolidate the strategic support for the modernisation of Micro, Small and Medium-sized companies.

▶ Mozambique debates eco-industrial parks

How industrial parks can be managed in a sustainable way in Mozambique was the topic of the seminar’s debate on the implementation of approaches to Eco-Industrial Parks (EIP) in Mozambique, held by ICRFacility Mozambique, a company that provides technical assistance to facilitate development of eco-industrial parks in the country. The debate, which took place online, was attended by representatives of the European Union in Mozambique and the Beluluane Industrial Park.

Sofala, Manica and Tete

An industry to transform lives

If the growth of a country’s economy is measured by the growth of the industry sector, the success of the industry sector is measured (or should be measured) by the involvement of the communities that surround them, the sense of belonging that makes the endeavour a community flag. And making with the community for the community and for others seems to be the mantra of the industries we visited in Sofala, Manica and Tete provinces, an industry to transform lives.

If the growth of a country’s economy is measured by the growth of the industry sector, the success of the industry sector is measured (or should be measured) by the involvement of the communities that surround them, the sense of belonging that makes the endeavour a community flag. And making with the community for the community and for others seems to be the mantra of the industries we visited in Sofala, Manica and Tete provinces, an industry to transform lives.

These provinces, which are part of the central region, have already demonstrated their role in Mozambique’s industrial circuit, with a variety of sectors, ranging from agro-industry to extractive industry, to the manufacturing industry.

The Port of Beira has been the driving force of the region, managed by Cornelder of Mozambique, which directly links, either by road or rail, the main markets of the southern African hinterland, such as Zimbabwe, Malawi, Zambia, Botswana, the Democratic Republic of Congo, as well as the local market, and the international trade routes. It always ends up being strategic for the internationalisation of local and regional production.

If, from the point of view of infrastructure, the Port of Beira is the standard bearer of Sofala, from the point of view of industry the Mafambisse sugar refinery takes that spot. But there are other ventures, especially in the food industry.

Manica, on the other hand, is a province with great agro-ecological potential, where the climate, soil and terrain are favourable to agricultural and livestock production and forestry, with emphasis on cereals, cattle, native and exotic forest species. In the creation, processing and commercialisation of cattle, the company Moz Bife stands out, based in the district of Chimoio; in the raising, processing and commercialisation of chickens, Agro-pecuária e Avícola Abílio Antunes based in the district of Vandúzi; MOZAGRI, based in the District of Báruè, dedicates to raising, processing and sale of kid meat; the company DAN MOZ and Agromaco are dedicated to the production and commercialisation of yogurt, all based in the Chimoio District, in addition to small players located in other districts. Fisheries has also been a path that the province has been following. It represents more than 10,000 tons of fish per year.

Still in Manica, we visited the Mozambique Fertilized Company, a company dedicated to the production of fertilizers that serve as a basis for increasing the production of multiple agricultural crops by local farmers, which is also exported to countries like Zimbabwe. But there is also hydrographic potential and mineral resources such as gold, tourmaline, construction materials and mineral water.

The province of Tete is another hub to be taken into account. For two decades now, it has come to be considered the country’s El Dorado because it possesses one of the largest mineral coal deposits. The extractive industry in Tete is the sector that almost outshines the remaining activities, with 85% of the province’s revenues coming from coal, and it is also responsible for sparking other sectors, especially those providing services and goods through small and medium-sized companies (SMEs).

In addition to mineral coal, we can also find in Tete one of the largest hydroelectric dams in Africa, the Cahora Bassa Hydroelectric, the 18th most important in the world, with a maximum annual production capacity of 18,000 GWh and which supplies the country and neighbours like South Africa, Malawi, Zambia, Zimbabwe. A project for energy production through coal produced in Moatize is in the works.

CASE STUDIES

Cahora Bassa Hydroelectric

The light for the future

In the country, whenever electricity is mentioned, we are referred to the Cahora Bassa Hydroelectric (HCB), despite the fact that Electricidade de Moçambique (EDM) is the entity managing the electrical grid. Of course, EDM is a supplier, but there are those who produce it, which is HCB in this case, thus playing a fundamental role in the national energy system.

Although the Covid-19 pandemic has shaken almost all institutions in the world, including Mozambique, HCB has, so far, seemed unfazed, as it has managed to surpass the energy production target set for 2020. According to data disclosed by the company, in 2020, production stood at 15,302 gigawatts, a figure that represents a 4.7% increase over the production of the previous year.

For HCB’s managers, “this result was only possible thanks to the plans to modernise the electricity generation park and the operation and maintenance processes that have been implemented, with the aim of improving energy reliability and equipment availability.”

More than that, there are future plans that aim to make this company increasingly sustainable. To this end, HCB’s management understands that the future of HCB is to increase its installed capacity of 2,075MW within the next ten years, in order to meet national and regional demand.

DECA and the empowerment of small producers

DECA, Desenvolvimento Comercial Agrícola, was established in 2005. But it was only in 2008 that activities started. The first three years were focused on contacting local farmers to ensure the production of cornmeal. The company never had farms. From the first moment, it set itself out to be the one who processes, leaving the previous part, that of the production of raw material, in this case corn, to local farmers. At first they were not even 500, but after more than 10 years, the records show about 220,000.

DECA tries its best to avoid middlemen, always seeking to buy corn directly from small local farmers, through a purchasing network established at specific points throughout the Chimoio region. “It is our way of emancipating the community,” the factory team tells us. There are no minimum purchase limits, from the farmer who proposes to sell only 10 kilos to the one who proposes to sell tons, there is space for everyone.

The corn is then transported to the processing and storage facilities specifically built by DECA in Chimoio, where it is dried, fumigated, prepared and transformed into cornmeal, a basic staple in the region and in the country as a whole.

Today, DECA is a reference in the central region. After the processing of cornmeal came the production of puffs and Nik Naks, bran and feed, and the processing of beef, which is sold under the Mozbife label. Cattle are also bought from local breeders. There are now around 20,000 suppliers, and the company has a ranch that is dedicated to improving cattle through fattening before slaughter.

Mafambisse Sugar Refinery

A community partner

The sugar refinery ended up bearing the name of the Administrative Post in which it is located, Mafambisse. But it’s not just the name. This refinery sources the overwhelming majority of its 1,500 workers from this Administrative Post. But there is more: despite having its own cane field, which continues the practive of manual cutting so that workers don’t lose their job, 12% of the production comes from the community, with their own farms, a percentage which can always go up.

Nowadays, with the need for crop rotation, a rice cultivation project was started on a land loan scheme, to local farmers, for up to 10 years. The first harvest has already begun and a rice factory is in the process of being opened, a partnership between the factory and the community.

But there is also the creation of tilapia fish in nurseries, a project idealized and promoted by the sugar producer in partnership with local fish farmers, which also serves to generate income and empower families in the surrounding areas.

With an annual production of more than 30,000 tons, distributed to the entire central and northern regions and also exported to Europe, the Mafambisse sugar refinery saw Covid-19 change the weight at the scale. Production fell short, first of all because the restrictions imposed by the pandemic have slowed planting and harvesting. But because the pandemic does not seem ready to give up anytime soon, the sugar refinery must adapt to the new reality and seek to surpass the overall numbers of 2020.

Industry Especial | Download

0 Comments